Understanding SPC Parameters: Cp, Cpk, Cpm, Pp, and Ppk Explained | Lab Wizard

Table of Contents

Understanding SPC Parameters: Cp, Cpk, Cpm, Pp, and Ppk Explained

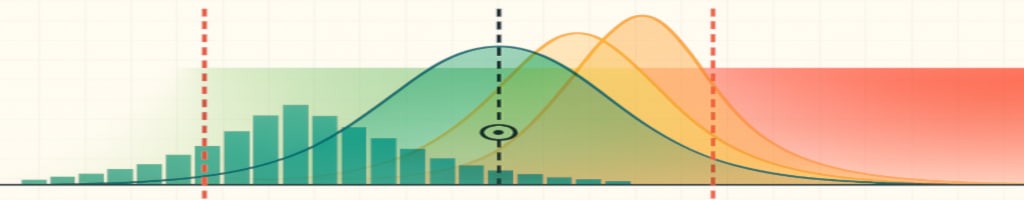

Statistical Process Control (SPC) uses capability indices to measure how well a process meets its specification limits. These indices give manufacturers and auditors an objective way to evaluate stability, performance, and quality risk.

Below are five commonly used SPC indices with example values:

SPC Capability Indices Overview

Quick reference for understanding the five key SPC parameters and their meanings

| Parameter | Example | Meaning |

|---|---|---|

| Cp | 0.505 | Measures potential capability (spread vs. spec limits). Value < 1 indicates process spread is wider than the spec window. |

| Cpk | 0.403 | Accounts for centering. Low value shows the process mean is not centered within the spec limits. |

| Cpm | 0.482 | Considers deviation from the target, not just limits. Useful for processes where hitting the target is critical. |

| Pp | 0.504 | Short term process potential (uses overall standard deviation). Similar to Cp but for preliminary studies. |

| Ppk | 0.402 | Short term performance index accounting for centering. Often used in initial capability studies. |

⚡ Understanding Each SPC Parameter

Cp: Process Capability Index

- Definition: Compares the natural variation (6σ) to the specification width.

- Interpretation: Cp = 0.505 means the process spread is about half the width of the specification window, but not centered.

- Note: Cp does not consider centering.

Cpk: Process Capability Index (Centered)

- Definition: Adjusts Cp by accounting for process centering.

- Interpretation: Cpk = 0.403 indicates that even if Cp is ~0.5, the process is shifted off-center, lowering its actual capability.

Cpm: Taguchi Capability Index

- Definition: Measures deviation from the target, not just limits.

- Interpretation: Cpm = 0.482 shows the process is not only wide but also not hitting the target.

- Use Case: Situations where “on target” is as important as being within specs.

Pp: Preliminary Process Capability

- Definition: Uses total variation (overall standard deviation), suitable for short term studies.

- Interpretation: Pp = 0.504, very similar to Cp in this case, confirming spread issues exist.

Ppk: Preliminary Process Capability (Centered)

- Definition: Like Pp, but considers centering.

- Interpretation: Ppk = 0.402, showing that in short term data, the process mean is still off-center.

🚦 Interpreting These Results

With Cp = 0.505 and Cpk = 0.403:

- The process cannot consistently meet specifications (values < 1.0).

- Centering issues make capability worse (Cpk < Cp).

- Both short-term (Pp/Ppk) and long-term (Cp/Cpk) indices show the same pattern.

Process Capability Guidelines:

Capability Index Interpretation Guide

Use this table as a reference for interpreting Cp and Cpk values in manufacturing processes

| Index Range | Process Capability | Action Required |

|---|---|---|

| ≥ 2.0 | Excellent | Monitor and maintain |

| 1.67 - 1.99 | Very Good | Continue current process |

| 1.33 - 1.66 | Good | Minor improvements may help |

| 1.0 - 1.32 | Marginal | Process improvement needed |

| < 1.0 | Poor | Immediate action required |

Key Takeaways

- Cp vs. Cpk: Cp shows potential capability, Cpk shows actual performance.

- Pp vs. Ppk: Preliminary indices for early studies.

- Cpm: Focuses on hitting the target.

- Rule of Thumb: Aim for Cp/Cpk ≥ 1.33 for capable processes.

Implementation Tip: Start with Cpk analysis for your most critical quality parameters. Once you understand your current capability, use control charts to maintain and improve process stability.

🚩 Common SPC Capability Analysis Mistakes

❌ Using Cp/Cpk with unstable processes → Capability indices are meaningless without statistical control. Always establish process stability with control charts before calculating capability.

❌ Confusing Cp with Cpk significance → A high Cp (1.8) with low Cpk (0.9) indicates centering problems, not good capability. Focus on Cpk for actionable insights.

❌ Mixing short term and long term indices → Don’t compare Pp values from 30-day studies with Cp values from 6-month data. Use consistent timeframes for meaningful comparisons.

❌ Ignoring sample size requirements → Calculating capability with <30 data points produces unreliable results. Ensure adequate sample sizes before drawing conclusions.

❌ Using capability indices for non normal data → Cp/Cpk assume normal distribution.

❌ Calculating capability during process changes → Recipe adjustments, equipment maintenance, or operator changes invalidate existing capability calculations. Recalculate after stabilization.

❌ Focusing only on Cpk without understanding root causes → A Cpk of 0.4 tells you there’s a problem but not why. Use control charts and process analysis to identify improvement opportunities.

Related SPC Resources and References

Learn more about statistical process control and capability analysis:

Lab Wizard SPC Resources:

- Western Electric Rules for SPC: Implementation Guide - Learn pattern detection for early process intervention

- Control Limits vs. Specification Limits vs. Optimal Limits - Master the different types of limits in SPC

- SPC in Plating 101 - Comprehensive introduction to statistical process control

External References:

- NIST Engineering Statistics Handbook - Process Capability - Comprehensive technical reference for capability indices and calculations

- ASQ Process Capability Studies - American Society for Quality standards and best practices for capability analysis

Transform your quality control from reactive to predictive with systematic SPC capability analysis in Lab Wizard.