Western Electric Rules for SPC: Implementation Guide | Lab Wizard

Table of Contents

Western Electric Rules Explained: 4 SPC Tests for Early Process Detection

Western Electric Rules are four statistical tests applied to control charts that detect non random patterns before processes drift out of specification. These SPC rules identify subtle process shifts through pattern recognition, like consecutive points trending in one direction or clustering near control limits, enabling early intervention before quality issues occur.

Lab Wizard’s configurable Western Electric Rules implementation helps manufacturing teams detect process drift early, reduce false alarms through intelligent pattern recognition, and maintain audit ready documentation of process control responses.

What Are the 4 Western Electric Rules?

Western Electric Rules transform statistical process control from reactive alarm systems into proactive pattern detection. Rather than waiting for individual points to exceed control limits, these four tests identify subtle patterns that signal special causes requiring investigation.

The 4 Western Electric Rules (Quick Reference)

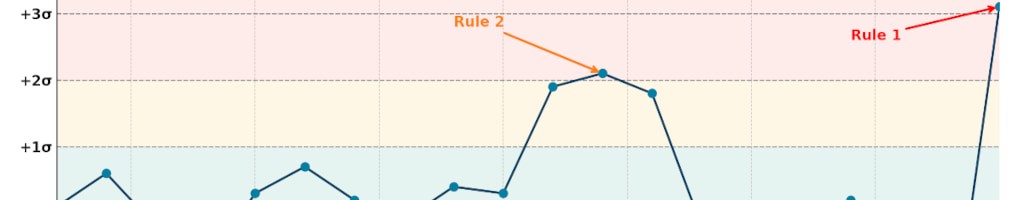

- Rule 1: One point beyond 3-sigma control limits (either side)

- Rule 2: Two of three consecutive points beyond 2-sigma on same side

- Rule 3: Four of five consecutive points beyond 1-sigma on same side

- Rule 4: Eight consecutive points on same side of centerline

Originally developed by Western Electric Company for telecommunications equipment manufacturing, these rules have become the foundation for modern statistical process control across all industries.

⚡ Understanding Each Western Electric Rule

Rule 1: Single Point Beyond 3σ One point beyond the 3-sigma control limit on either side of the centerline indicates a strong special cause requiring immediate investigation. This is the most critical Western Electric Rule.

Rule 2: Two of Three Beyond 2σ Two out of three consecutive points beyond the 2-sigma limit on the same side of the mean suggests the process is shifting toward one direction. This pattern indicates a developing special cause.

Rule 3: Four of Five Beyond 1σ Four out of five consecutive points beyond the 1-sigma limit on the same side of the mean indicates a sustained shift in the process average. This detects gradual process changes.

Rule 4: Eight Points on Same Side Eight consecutive points on the same side of the centerline (some organizations use 9 points - maintain consistency) detects gradual process drift and systematic variation.

Implementation Tip: Ensure you have sufficient baseline data (typically ≥20-25 subgroups, in Lab Wizard you can view charts by date range or number of data points) to establish stable mean and standard deviation before enabling Western Electric Rules.

How to Apply Western Electric Rules in Chemical Plating

In electroplating operations, critical parameters like chemical concentration, rectifier current/voltage, bath temperature, and pH/conductivity often drift gradually before causing visible quality issues. Traditional limit checking only catches problems after they’ve already impacted production.

Early Detection Benefits in SPC:

- Prevent scrap and rework by catching drift before specification violations

- Maintain audit compliance with documented special cause detection and response

- Optimize chemical consumption by detecting bath chemistry changes early

- Reduce process variation through systematic pattern identification

- Improve yield consistency by maintaining tighter process control

Western Electric Rules excel at detecting the slow, systematic changes common in chemical processes that simple limit checking often misses until significant quality impact occurs.

Step by Step Implementation Without Alert Fatigue

The biggest mistake in Western Electric Rules implementation is enabling all rules for all parameters simultaneously, creating overwhelming alert volume that teams quickly ignore.

Phase 1: Foundation (Weeks 1-2)

- Enable Rule 1 only (3σ points) for SPC implementation

- Scope to 1-2 most critical KPIs that directly drive defects

- Define clear actions: “If Rule 1 triggers → verify instrument calibration, check for load/recipe changes, document corrective action”

- Establish response owners and timeframes

Phase 2: Pattern Detection (Weeks 3-4)

- Add Rules 2 and 3 for the same critical KPIs

- Classify Rule 1 as “Critical” (red), Rules 2-3 as “Investigate” (yellow)

- Review weekly: assess nuisance alert rate and confirm rational subgrouping

- Recalculate process limits after any genuine process changes

Phase 3: Trend Monitoring (Week 5+)

- Enable Rule 4 for parameters prone to slow drift (pH, temperature)

- Add standard operating procedures: “If Rule 4 triggers → check setpoints, agitation systems, heater/chiller performance, recent chemical additions”

- Expand to additional KPIs based on Phase 1-2 success

Western Electric Rules Action Guide: What to Do When Rules Trigger

Clear response protocols prevent confusion and ensure appropriate urgency for different Western Electric Rule violations:

🔴 Act Now Level (Rule 1)

- Immediate response required for SPC control

- Verify instrument calibration and process conditions

- Implement corrective action before next production lot

- Document in audit trail with closure verification

🟠 Investigate Level (Rule 4 or Repeated Watch)

- Assign specific owner for investigation

- Check recent process changes, material lots, equipment status

- Log probable cause analysis in Lab Wizard

- Implement containment if pattern continues

🟡 Watch Level (Rules 2-3)

- Increase sampling frequency for control chart monitoring

- Confirm instrument readings

- Document pattern in station history

- Monitor for escalation within 24-48 hours

SPC Setup Essentials: 5-Minute Implementation Checklist

✅ Stable Baseline Data Collect at least 30-60 data points under normal operating conditions. Recalculate mean and standard deviation after process improvements or equipment changes by selecting by date range.

✅ Consistent Western Electric Rules Conventions Pick one convention for Rule 4 (7 or 8 consecutive points) and apply consistently across all control charts. Document your choice in SPC procedures.

✅ Defined Response Ownership Alert specific users for each rule level response. No mystery alerts, everyone knows what actions to take for each Western Electric Rule.

✅ Weekly SPC Reviews Track alerts per KPI, false positive rates, and top special causes. Use this data to refine subgrouping and rule sensitivity in your control charts.

🚩 Common Western Electric Rules Implementation Mistakes

❌ Enabling all Western Electric Rules for every metric on day one → Creates instant alert fatigue and team resistance to SPC

❌ Using stale control limits after recipe or hardware changes → Generates false alarms and reduces trust in the Western Electric Rules system.

❌ Skipping response documentation → Auditors require evidence of signal detection, investigation, and corrective action closure for SPC compliance

❌ Ignoring baseline stability → Western Electric Rules are meaningless without statistically valid control limits from stable process data.

Recommended Starting KPIs for Western Electric Rules in Chemical Plating

Solution Analysis Results Tracks metal concentration, additive levels, and impurity buildup patterns that indicate when chemical maintenance is required using control chart analysis.

Rectifier Current (Amperes) Detects load variations, contact issues, anode/cathode problems, and solution conductivity changes that directly impact plating thickness and uniformity on control charts.

Bath Temperature (°C/°F) Identifies heater/chiller drift, agitation effects, and thermal control issues that affect deposition rate and solution stability in SPC monitoring.

pH / Conductivity Monitors chemical addition timing, drag-in/drag-out effects, and rinse water contamination that impacts solution chemistry balance through Western Electric Rules.

Advanced SPC Implementation: Beyond Basic Western Electric Rules

Once Western Electric Rules are stable and providing value in your SPC system, consider expanding pattern detection capabilities:

Automated Response Integration Link Western Electric Rule violations to automatic alerts, sampling schedules, equipment maintenance triggers, or chemical addition protocols where appropriate.

Predictive Trending Use rule patterns to predict when routine maintenance or chemical adjustments will be needed, shifting from reactive to preventive management in SPC.

Measuring SPC Success: Western Electric Rules Performance Indicators

Track these metrics to demonstrate Western Electric Rules value in your SPC implementation:

- Special cause detection rate - Number of confirmed process issues caught before specification violations using control charts

- False alarm reduction - Decrease in nuisance alerts compared to simple limit checking in SPC systems

- Response time improvement - Faster identification and resolution of process problems through Western Electric Rules

- Quality metrics - Reduction in scrap, rework, and customer complaints with improved control chart monitoring

- Audit compliance - Complete documentation trail for regulatory reviews of SPC implementation

Successful Western Electric Rules implementations typically show 30-50% reduction in specification violations and 40-60% improvement in special cause detection speed.

Related SPC Resources and References

Learn more about statistical process control and Western Electric Rules implementation:

Lab Wizard SPC Resources:

- Understanding control limits and specification limits in SPC - Master limit types and interactions for effective control charts

- Configure intelligent SPC alerting systems - Set up Western Electric Rules alerts and notifications

- Apply SPC methods across manufacturing processes - Comprehensive statistical process control implementation guide

External References:

- NIST Engineering Statistics Handbook - Control Chart Interpretation - Comprehensive technical reference for Western Electric Rules and SPC

- ASQ Control Charts Resources - American Society for Quality standards and best practices for statistical process control

Transform reactive process monitoring into proactive pattern detection with systematic Western Electric Rules implementation in your SPC system.