MSA in Plating Labs: Gage R&R for Titration & pH | Lab Wizard

Table of Contents

What is MSA? What is Gage R&R?

MSA (Measurement System Analysis) evaluates whether your measurement process is fit for purpose by quantifying its variation and bias. Gage R&R is the core MSA study that partitions measurement variation into repeatability (equipment) and reproducibility (between operator) components.

Why Gage R&R matters in plating labs (titration & pH specifics)

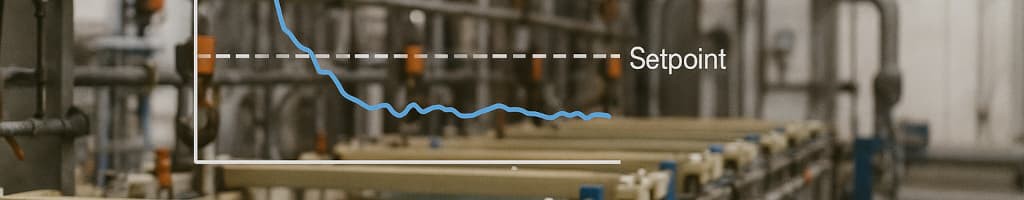

Plating chemistries live on narrow control windows. Titration results drive additions; pH drives reaction rates and deposit quality. If the measurement system is noisy, you will over correct baths, misclassify parts, and chase phantom trends. Gage R&R confirms that your titration method and pH measurement can distinguish real process change from measurement noise.

Study design: parts, operators, trials (3×10 typical), randomization, environmental control

- Design: 10 distinct parts/samples × 3 operators × 3 trials (total 90 readings).

- Parts: Span normal operating range (low/nominal/high). For titrations, prepare consistent test samples; for pH, use well-mixed working solutions.

- Operators: Trained, representative of routine users.

- Trials: Blind and randomized order to avoid memory and drift effects.

- Control environment: Temperature control (pH is temperature sensitive), consistent lighting for color endpoints, fresh buffers/standards, clean glassware/electrodes.

Step by step: Run a 3×10 Gage R&R on a pH meter

- Prepare two or three fresh pH buffers representing your operating range; verify meter/electrode health.

- Calibrate at working temperature; document stabilization criteria (e.g., drift <0.01 pH in 10 s).

- Select 10 samples that cover expected variation (or prepare standards).

- Randomize a run sheet of 90 measurements (10 parts × 3 operators × 3 trials).

- Train operators on identical handling: rinse, blot (no wiping), immerse to junction depth, swirl, wait for stability, read, record.

- Record metadata: operator, part_id, trial, reading, instrument_id, temperature, timestamp.

- Control drift: Re-check a mid range buffer every ~15 readings; note any offset/drift.

- Maintain consistency: Same beaker size, sample volume, and stir/no-stir rule.

- Complete all trials following the run sheet without revealing prior readings.

- Export the dataset to CSV and compute GRR via range method or ANOVA.

⚡ Calculations: Range method vs. ANOVA

Basic notation:

GRR (Gage Repeatability & Reproducibility)

ndc (Number of Distinct Categories)

- EV = Equipment Variation (repeatability)

- AV = Appraiser Variation (reproducibility)

- GRR = Gage Repeatability & Reproducibility sqrt(EV² + AV²)

- PV = Part-to-Part Variation

- %GRR = 100 × GRR / PV

- ndc ≈ 1.41 × PV / GRR

Range method (quick screen; uses AIAG constants)

Compute average within part range across operators/trials: r̄

Repeatability:

EV = r̄ / d₂(n) (for n = trials per part; e.g., d₂(3) ≈ 1.693)For reproducibility, get the range of operator means for each part, average to R̄ₓ̄, then:

AV = sqrt(max((K × R̄ₓ̄)² - EV², 0))

(K depends on number of operators and trials; from AIAG table)Part variation (shortcut):

PV ≈ s_part_means / c₄ (or use AIAG shortcuts)Combine:

GRR = sqrt(EV² + AV²), %GRR = 100 × GRR / PV, ndc ≈ 1.41 × PV / GRR

ANOVA method (preferred for unbalanced/more exact studies)

Two way random effects ANOVA (factors: Part, Operator; crossed) with replication.

Let mean squares be:

- MS_E = error

- MS_P×O = part by operator interaction

- MS_O = operator

- MS_P = part

Let n_r = trials per cell, n_o = operators, n_p = parts.

Variance components (set any negative to zero via max(…,0)):

- σ²_E = MS_E

- σ²_P×O = (MS_P×O - MS_E) / n_r

- σ²_O = (MS_O - MS_P×O) / (n_p × n_r)

- σ²_P = (MS_P - MS_P×O) / (n_o × n_r)

Then:

- EV = sqrt(σ²_E)

- AV = sqrt(σ²_O) (optionally add σ²_P×O into GRR if practically significant)

- GRR = sqrt(σ²_E + σ²_O)

- PV = sqrt(σ²_P)

Finally compute %GRR and ndc using the formulas above.

🚦 Interpreting results: %GRR, ndc, acceptance bands

A compact rule set for routine lab use:

| Metric | Band | Interpretation |

|---|---|---|

| %GRR | < 10% | Good: Suitable for control charts and acceptance. |

| %GRR | 10–30% | Marginal: Use with caution; improve if feasible. |

| %GRR | > 30% | Unacceptable: Not suitable, fix the system first. |

| ndc | ≥ 5 | Minimum useful resolution across the process range. |

| ndc | ≥ 10 | Preferred for fine control and optimization. |

When %GRR is marginal or poor, inspect EV vs. AV to decide whether to improve the instrument/method (EV) or training/standard work (AV).

🚩 Common pitfalls (plating specific)

- pH temperature effects not matched to process temperature.

- Electrode issues: old junctions, dried glass, poor storage, CO₂ absorption in open beakers.

- Endpoint subjectivity in colorimetric titrations; inconsistent lighting/background.

- Contaminated buffers/standards or expired solutions.

- Sample handling: poor mixing, air bubbles, carryover between titrations.

- Operator rounding/reading timing differences.

- Glassware calibration (burettes/pipettes) and rinse technique variation.

Template (CSV spec + mini example)

CSV columns (header row required):

part_id,operator,trial,reading,standard_value,instrument_id,timestamp

- part_id: sample identifier (e.g., S01…S10)

- operator: initials or code (e.g., OP1…OP3)

- trial: 1–3 for a 3×10 study

- reading: numeric measurement (pH or titration result)

- standard_value: true/assigned value (if applicable)

- instrument_id: meter or burette ID

- timestamp: ISO 8601

Tiny example (8 rows):

| part_id | operator | trial | reading | standard_value | instrument_id | timestamp |

|---|---|---|---|---|---|---|

| S01 | OP1 | 1 | 6.98 | 7.00 | PHM-01 | 2025-08-28T10:01:00Z |

| S01 | OP2 | 1 | 7.02 | 7.00 | PHM-01 | 2025-08-28T10:04:12Z |

| S01 | OP3 | 1 | 7.01 | 7.00 | PHM-01 | 2025-08-28T10:07:25Z |

| S05 | OP1 | 2 | 5.45 | 5.50 | PHM-01 | 2025-08-28T10:20:10Z |

| S05 | OP2 | 2 | 5.52 | 5.50 | PHM-01 | 2025-08-28T10:23:03Z |

| S05 | OP3 | 2 | 5.49 | 5.50 | PHM-01 | 2025-08-28T10:25:59Z |

| S09 | OP1 | 3 | 9.07 | 9.00 | PHM-01 | 2025-08-28T10:40:44Z |

| S09 | OP2 | 3 | 9.02 | 9.00 | PHM-01 | 2025-08-28T10:43:36Z |

Tip: Include a separate buffers.csv (buffer value, lot, exp date) for traceability.

Why This Matters in Lab Wizard

Strong data = strong decisions.

Lab Wizard’s SPC charts, alerts, and audit trails are only as good as the measurements feeding them.By validating titration and pH systems with a proper Gage R&R study, you ensure:

- Reliable SPC: Control limits and capability indices reflect the true process, not instrument noise.

- Accurate alerts: Out-of-control signals in Lab Wizard trigger when the process shifts, not when the electrode drifts.

- Audit confidence: Demonstrating an MSA study backs up your compliance with NADCAP, AS9100, ISO 17025, and customer quality audits.

Use this guide to check your measurement systems, then let Lab Wizard turn that validated data into real-time insights and audit-ready records.

Related MSA Resources and References

Learn more about measurement system analysis and Gage R&R studies:

Lab Wizard MSA Resources:

- Control Limits vs. Specification Limits vs. Optimal Limits - Master the different types of limits in SPC

- Western Electric Rules for SPC: Implementation Guide - Learn pattern detection for early process intervention

- Understanding SPC Parameters: Cp, Cpk, Cpm, Pp, and Ppk Explained - Comprehensive guide to capability indices

- Lab Wizard Alerts Tutorial - Set up automated quality alerts

External References:

- AIAG MSA Manual (4th Edition) - Industry standard reference for measurement system analysis methodology and protocols

- ASQ Measurement System Analysis - American Society for Quality training and best practices for MSA implementation

- NIST Engineering Statistics Handbook - Measurement Process Characterization - Comprehensive technical reference for MSA principles and statistical methods

Validate your measurement systems first, then let Lab Wizard transform that trusted data into actionable insights and audit-ready documentation.

Key takeaways

- Run 3×10 randomized studies under controlled conditions; record full metadata.

- Target %GRR < 10% and ndc ≥ 5 (≥ 10 preferred) before trusting control decisions.

- Use ANOVA for accuracy and diagnostics; range method for quick screens.

- If EV dominates, fix the method/instrument; if AV dominates, fix training/standard work.

- For titrations and pH, temperature, buffers, and lighting are make or break variables.