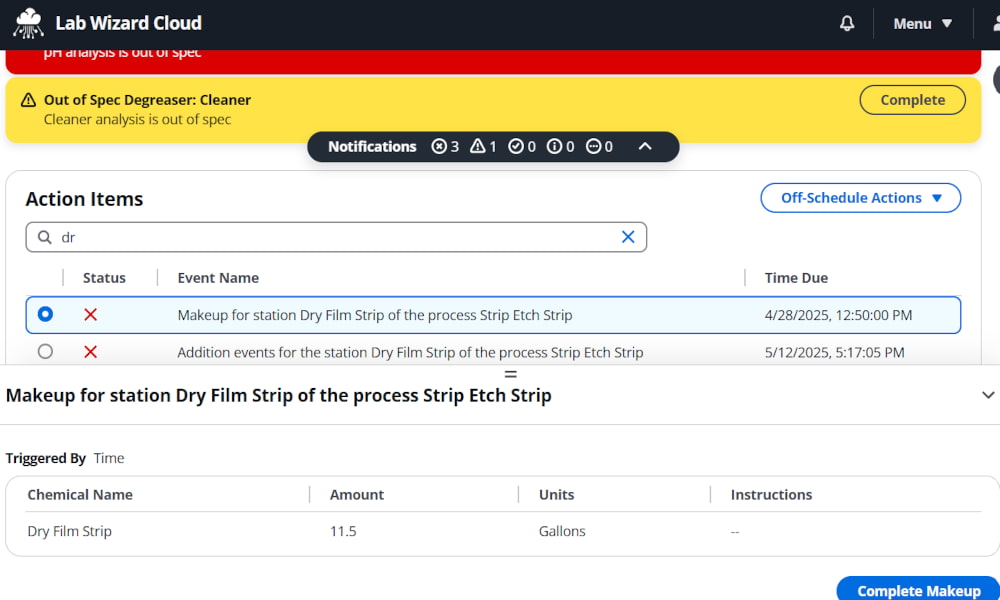

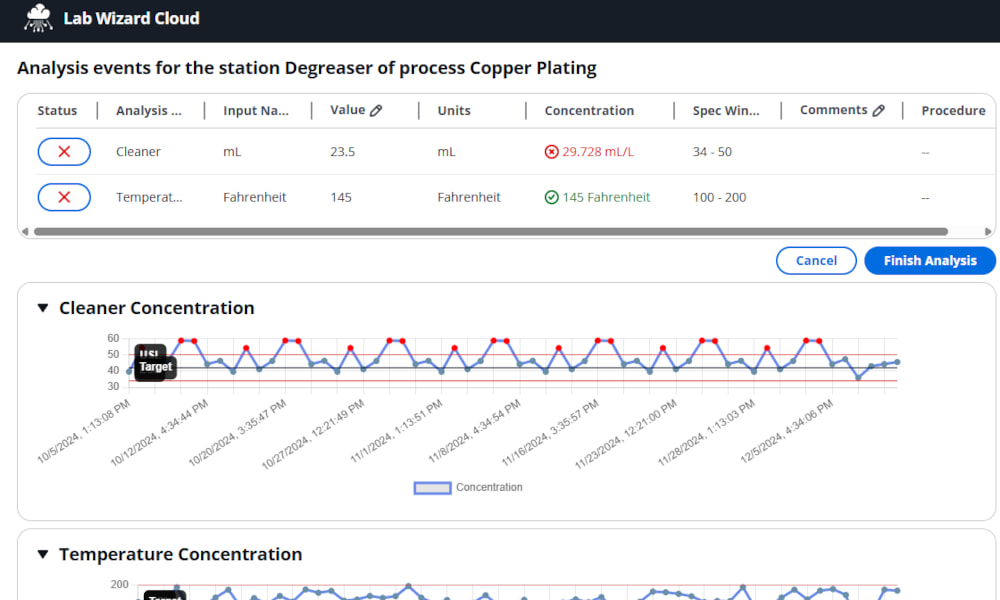

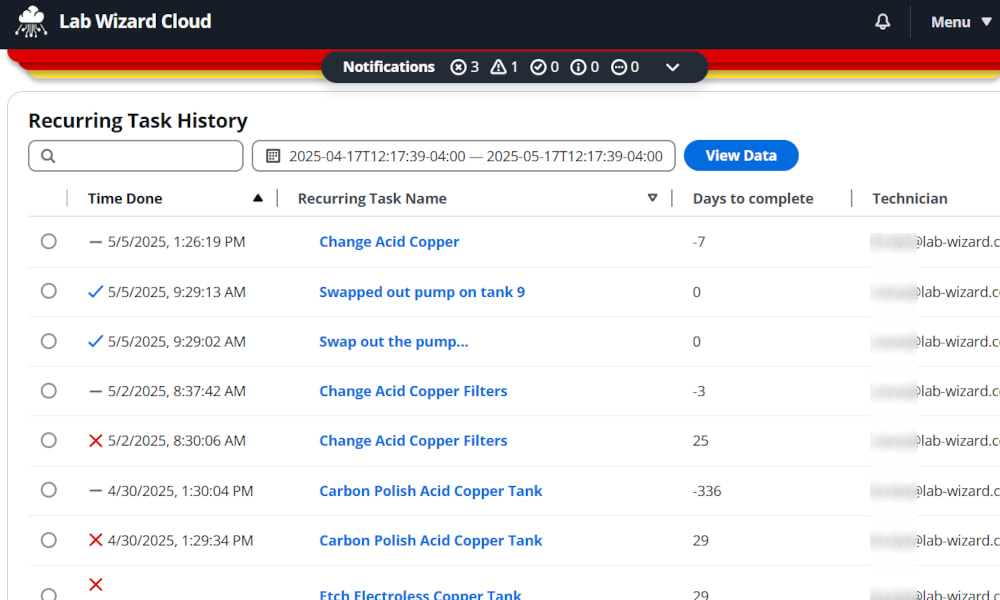

By unifying your chemical data, tank parameters, and alert logic into one centralized platform, Lab Wizard Cloud breaks down the silos that limit quality and speed. It enables real-time alerting across disparate systems, from lab analysis to rectifier performance, all tied together with deep traceability and control.

The result is more than just monitoring, it’s a single source of truth designed for full-scale Industry 4.0 operations, scalable for future AI-driven insights, predictive analytics, and fully automated compliance management.

While our Desktop version remains supported and dependable, Lab Wizard Cloud is where all new features, integrations, and innovations will live.

Learn more about our security-first approach →